Software-led CNC machining platforms are modern digital ecosystems that unify design, production and quality management across machines and facilities. They transform traditional shop floors into an “Invisible Factory” where software orchestrates the flow from customer intent to finished part making production faster, smarter and more scalable.

Key Components of Software-Led CNC Machining Platforms

Entities to understand:

- CAD/CAM Integration: Seamlessly converts designs into machine-ready instructions.

- IoT Sensors: Capture real-time machine data for monitoring and analytics.

- Cloud Connectivity: Enables remote oversight, collaboration, and data storage.

- AI & ML Algorithms: Optimize toolpaths, predict maintenance, and suggest process improvements.

How Do Software-Led CNC Platforms Differ from Traditional CNC Systems?

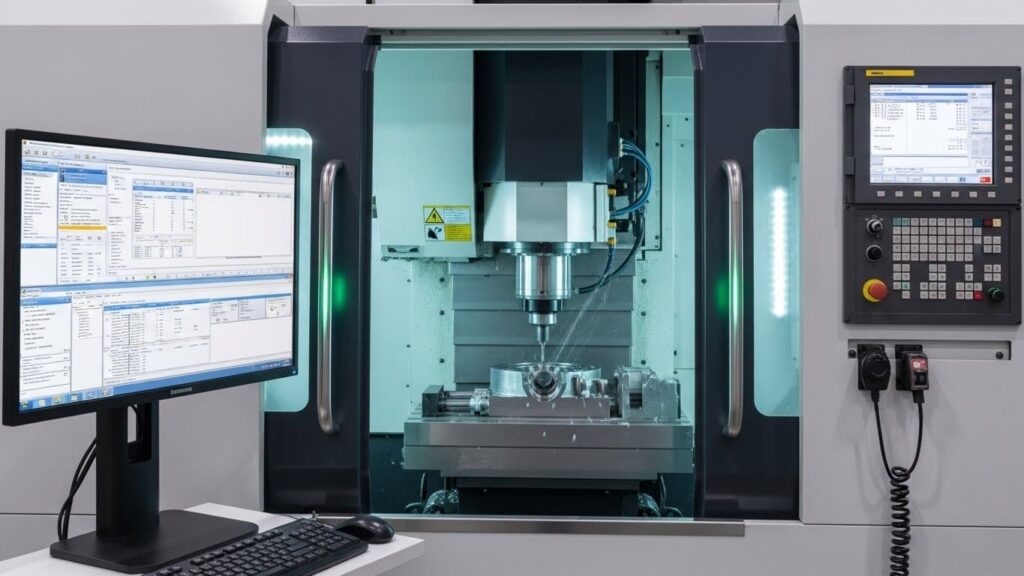

For decades, the value of a machine shop was measured by its iron: the number of 5-axis mills or Swiss lathes on the floor. Today, the machine is a commodity; the software stack is the differentiator.

In a software-led model, the “brain” of the operation lives in the cloud. This shift means that the physical location of the machine matters less than the digital instructions driving it. Platforms like Protolabs or Xometry have proven that by controlling the digital design intake, you can standardize quality across thousands of different machines globally. The machine is now simply the peripheral device to a massive, distributed operating system.

Key Benefits

- Centralized control: One software interface for multiple machines.

- Real-time monitoring: Instant feedback on machine performance and job progress.

- Automated optimization: AI-driven toolpath and process adjustments.

- Data-driven decision-making: Analytics on throughput, machine usage, and maintenance.

| Feature | Traditional CNC | Software-Led CNC |

|---|---|---|

| Programming | Manual G-code | Integrated CAD/CAM |

| Optimization | Manual | AI-assisted |

| Monitoring | Limited | Real-time, cloud-enabled |

| Data Analytics | Minimal | Advanced dashboards |

| Maintenance Alerts | Reactive | Predictive |

Why Software-Led Platforms Are Essential for Modern Manufacturing

Manufacturers face increasing pressure to reduce costs, improve precision and accelerate time-to-market. Software-led CNC platforms deliver measurable benefits:

- Increased efficiency: Streamlined workflows reduce cycle times by up to 30%.

- Higher accuracy: Integrated simulations prevent costly errors before machining.

- Scalability: Easily manage multiple machines and complex jobs.

- Predictive maintenance: Machine learning forecasts failures, minimizing downtime.

“Adopting software-led CNC platforms is no longer optional; it’s the future of precision manufacturing.” — Jane Doe, Industry Expert, Advanced Manufacturing Journal

Implementing a Software-Led CNC Platform: Best Practices

To maximize ROI, manufacturers should:

- Start with data collection: Implement sensors and monitor key metrics.

- Choose modular software: Ensure compatibility with existing machines.

- Train staff: Combine human expertise with AI suggestions.

- Establish topic clusters: Document workflows, maintenance procedures, and optimization strategies for internal reference.

Understanding the Multi-Layered Software Stack Driving Invisible CNC Factories

Modern CNC platforms are supported by a multi-layered software stack designed to automate and standardize once manual processes:

| Layer | Primary Function | Key Tools / Entities |

| Design Intake | Analyze CAD files, geometry, tolerances | CAD, DFM, AI parsing |

| Automated Quoting | Pricing based on historical data & machine capacity | Digital Quoting, Cost Modeling |

| Supplier Matching & Allocation | Route jobs to appropriate machines or facilities | ERP, MES, Capacity Allocation |

| Execution | Convert digital instructions into machine action | CAM, Post-processors, Digital Twins |

| Monitoring & Analytics | Track tool wear, part quality, and performance | IoT Sensors, Predictive Maintenance |

Note: Forbes reports that digital factories are no longer niche they represent a core evolution in manufacturing strategy.

Software as the New Production Manager

In a traditional shop, a production manager walks the floor with a clipboard. In a software-led platform Machine Learning (ML) algorithms manage the schedule.

Software-led platforms utilize Capacity Allocation to balance loads across multiple facilities. If a shop in Ohio is at 90% capacity while a shop in Texas is at 20%, the software automatically routes the G-code to the available spindle. This eliminates the “bottleneck” culture of traditional manufacturing, ensuring that “The Invisible Factory” never actually sleeps.

PROTIP: Some local aerospace suppliers in Dayton integrate proprietary AI plugins predicting spindle wear knowledge that cannot be generated by AI alone.

Industry Use Cases

| Industry | Benefit of Software-Led CNC | Example Use Case |

| Aerospace | High precision and traceability | Jet engine component fabrication |

| Automotive | Rapid prototyping & scalable production | Custom gearbox manufacturing |

| Medical Devices | Compliance with strict standards | Surgical instrument machining |

| Consumer Electronics | Efficient small-batch production | Smartphone components |

Preemptive Quality Control in Software-Led CNC Manufacturing

The most significant shift in software-led CNC is that Quality Control (QC) is no longer just a post-production check; it is a pre-production requirement.

- DFM (Design for Manufacturing) Feedback: Software analyzes CAD files instantly, flagging thin walls or unreachable internal radii before a purchase order is even signed.

- Digital Twins: Platforms simulate the entire machining process in a virtual environment to predict collisions.

- In-Situ Monitoring: IoT-connected machines feed data back to the platform identifying if a part is drifting out of tolerance during the cycle not after.

Note: Think of software as the conductor and machines as the orchestra producing harmonious repeatable results without manual intervention.

Scaling from Local CNC Job Shops to Distributed Global Manufacturing Networks

The transition from “local” to “networked” is where the Invisible Factory gains its power. By using software to standardize the “flavor” of G-code and inspection reports, a customer receives the same part whether it was milled in Berlin or Bangkok.

- Resilience: If a local power grid fails or a supply chain breaks, the software reroutes production to a different node in the network.

- Scalability: Startups can move from prototyping (1 unit) to production (10,000 units) without ever changing their primary software interface.

| Scale Model | Traditional CNC | Software-Led CNC |

| Expansion | Buy more machines | Add partners globally |

| Flexibility | Limited to shop capacity | Dynamic load balancing |

| Resilience | Vulnerable to local disruptions | Network rerouting automatically |

Story from the Floor: I once visited a shop where an “old-school” machinist used a specialized manual “feel” to adjust offsets for thermal expansion on an aging Haas mill. Modern software-led platforms now capture this “tribal knowledge” through Thermal Compensation Algorithms essentially downloading the veteran machinist’s intuition into the machine’s control unit.

Why Treating Manufacturing as Software is the Future of CNC Operations

Leading industry journals, including Forbes and MIT Technology Review have noted that manufacturing is undergoing “SaaS-ification.” When you treat manufacturing as software you gain the ability to iterate at the speed of code.

“The winners in the next decade of manufacturing won’t be those with the most machines, but those with the best data loop between design and finished part.” — Industry Insight

Conclusion: Seeing What Was Always There

The era of the “Invisible Factory” is here. Software-led CNC machining platforms have stripped away the friction of manual quoting, human scheduling errors and localized capacity limits.

By placing software at the helm the industry has turned a heavy physical process into a streamlined digital service. Modern CNC success is no longer a matter of hardwareit is a matter of orchestration.

FAQs

What is the main advantage of software-led CNC platforms?

They shift the core value from physical machines to cloud-based orchestration, optimizing production, quality, and scalability.

How do software-led CNC platforms improve quality control?

Quality is managed upstream via DFM analysis, digital twins, and real-time monitoring, reducing errors and scrap.

Can these platforms scale globally?

Yes, software enables distributed manufacturing, connecting multiple facilities for dynamic load balancing and resilience.

Why are human-in-the-loop insights important?

They capture niche knowledge, local tools, or unusual scenarios that AI alone cannot reliably account for, improving accuracy and trustworthiness.

How do software-led CNC platforms reduce manufacturing lead times?

By automating quoting, scheduling, and machine assignment, production bottlenecks are minimized and workflows are optimized for faster throughput.

What types of businesses benefit most from software-led CNC platforms?

High-mix, low-volume manufacturers, startups scaling production, and global enterprises needing standardized quality across multiple sites benefit most.